Slow destruction

CLAS inspectors and experts have experience of the blocks ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™ and Xbloc® more than 20 years.

This experiment is based on expertises of damaged breakwaters during construction or after construction. We have also inspected old ACCROPODE™ breakwaters to study the action of the time. We did a lot of repairs and reconstructions.

From this experience we have acquired a certainty:

The durability of breakwaters using ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™ and Xbloc® is closely linked to the care taken in the construction.

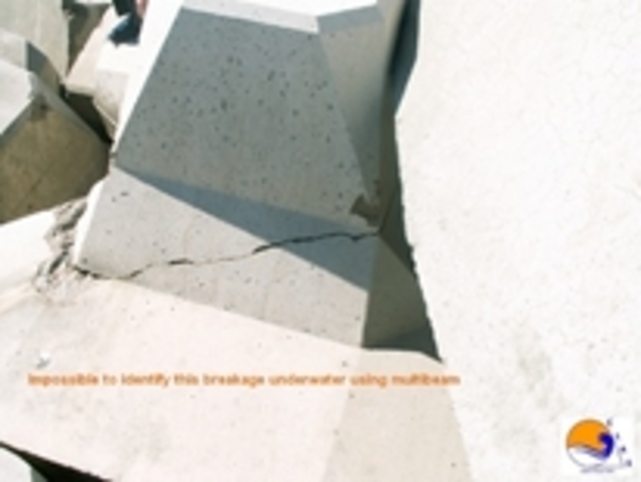

ACCROPODE™ broken totally invisible with acoustic tools if underwater or by boat even out of water

This includes the construction of the underlayment, the laying of the blocks, the quality of the supervision of the works and the techniques used to approve the construction.

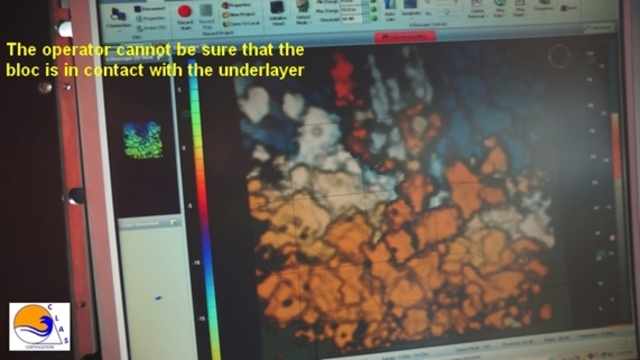

Underlayer approved by multi-beam while the slope consists of small materials normally used for the core.

The limits of acoustic or measuring instruments are not the only risk factors for the structure. The procedures set by engineers are also often one of those causes.

An example concerning the underlayment: the size of the riprap is tested and approved on quarry materials. These materials are stored on site. Because they are approved on paper they can be implemented. In the great majority of cases the engineers do not re-control at the time of actual implementation of these materials.

However, it often happens that the stocks are moved, that gear is rolling on stocks to dump other materials. This results in fragmentation. It is also possible that errors are made in the allocation of a stock. This is why CLAS inspectors are trained to determine how the dam is built in real time and not just on paper but actually in the sea.

An example regarding the blocks, they can be ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™ or Xbloc®: The X and Y position of each block is recorded. This is part of the "as built" and this data is used to calculate the packing density. We are often confronted with engineers who consider that H/12 precision must be applied to all blocks without exception. This is an aberration because what makes the structure solid and stable is the respect of the construction rules as defined in the TID, and in particular the quality of the interlocking wich is prior on the position X,Y. This imbrication is achieved by the physical contact of the blocks with each other, with some possible exceptions due to the adjustment of the blocks during the construction. The required accuracy H/12 relates to the first line for which there is no notion of inerlocking because it is placed on a flat riprap surface.

Link Importance of interlocking

So to satisfy the demands of the engineers, contractors are pushed either to pose with a correct imbrication and then register a false position to please them on paper, which does not weaken the work but produces false documents with all legal risks that this entails, either to actually place on the theoretical coordinates without looking for interlocking and in this case the construction is fragile with accumulations of contact defects, holes and blocks not interlocked.

The sea cannot read and a fragile work will be damaged even if it is solid on paper.

Large hole and major interlocking error on Xbloc® armour approved on paper

The construction has to be approved because there is formal proof that the design is respected on the built structure, that the interlocking of the blocks is good in the sea. That there are no out-of-profiles in the sea. That the first line is properly wedged by the toe mount protection in the sea etc... If not the movements will occur during the storms and will generate holes, large interlocking defects and block breaks.

Interlocking seen on the ECHOSCOPE : impossible to know if the blocks are properly interlocked

Link video DAS ISLAND Link ECHOSCOPE®

Interlocking seen on the POSIBLOC™ and monitored using the 3D view compared to the reality using pictures taken at the same time during the recording of the final position of the CORELOC™

So it exists in quality assessment procedures, what we call bad practices that consists in to ignore the limits of the tools and procedures and to substitute them for formal control by a human brain for construction in the sea. CLAS specializes in the study of these problems and provides solutions including when underwater visibility is very bad, by adding together complementary tools such as the use of ECHOSCOPE + a professional diving inspector. It is to this day the technical solution which gives the best results and brings a reliability similar to the inspection made in clear water by a professional diving inspector.

ACCROPODE™ which broke out of water two years after construction, following an unexpected settlement under water

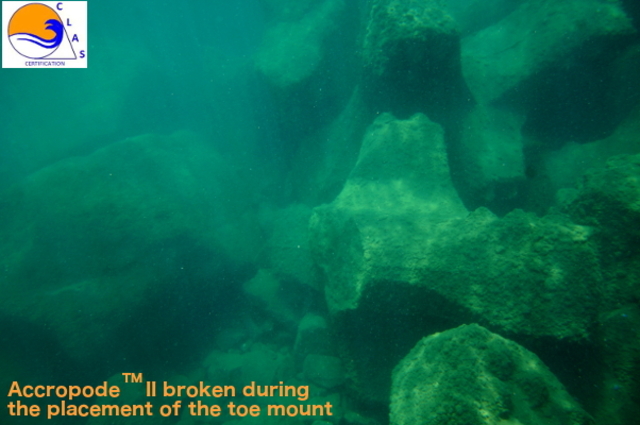

Block breaks are more frequent out of the water than under water. The break after the construction is caused by the movement of the block. The unit weight of the block under water is reduced by buoyancy. The speed of movement is reduced by the density of the water. Underwater movements rarely translate into breakage of the block. On the other hand out of the water, the block that moves can break and often a broken block out of the water indicates a movement under water. In case of breakage of blocks we must go to see under the sea what happens. This can be a simple adjustment without gravity or be the beginning of a slow degradation of the carapace.

Disconnection on an ACCROPODE™ armour due to instability in the deep part

These problems cannot be approached even in 3D models. These problems appear with time, storm after storm. The armour layer is slowly destroyed like the stitches of a knit and it is necessary to repair often with nautical means, after only a few years while the work was designed to hold more than 50 years.

There is a simple way to avoid this premature degradation. We must look after the construction and give ourselves the precise and effective means to control the reality of construction in the sea and not just on paper.

CLAS has established a classification of the ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™ and Xbloc® armours according to the care given to the construction. Link classification of armours.

INCREASING THE LIFE OF YOUR PROJECTS IS THE HEART OF OUR BUSINESS

Colapse

We define the collapse of all or part of the armour with ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ or X-bloc® by the overall movement which leads to the unraveling of the blocks and the need to remove them completely and to replace them.

Collapse of part of carapace ACCROPODE™

The collapse of a part of the carapace into blocks ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ or X-bloc® is a spectacular and violent phenomenon. These phenomena are rare and can be variable in intensity. The origin of the movement is a departure at the basis of the construction.

We have identified three unnatural causes, which can be the cause of the collapse of a part of the carapace:

1 A design error. Generally project swell that has been underestimated. Class A, B and C structures are exposed to this risk, which is aggravated by defects in construction.

2 Non-respect of design. It is always accompanied by deficiencies in external control. Class B and C structures are exposed to this risk, which is aggravated by construction defects. CLAS inspectors point out the non-respect of the design and require their rectification.

3 Level 3 non-conformities accumulated in the same zone. This can be Level 2 non-conformities that have not been processed in time and have evolved to level 3. In this case the collapse phenomenon can be established in several stages.

Link classification of armours

The tests with the 3D models make it possible to define the size of the carapace blocks which will be stable in front of a given wave. They do not allow to prevent construction defects and especially do not take into account the ruptures of blocks ACCROPODE ™, ACCROPODE ™ II, ECOPODE ™, CORELOC™ and XBLOC®.

During these tests these blocks are never broken when in reality, when they move they can break. Accumulated contact defaults can cause these settlement movements which are almost always accompanied by block breakage.

Broken blocks under water will be more easily removed by the swell and cause holes in depth that may cause collapse of part of the armour.

PRAT DE BAIX EDIFICI F PB3, SOLDEU, AD100 CANILLO

+376 354 698 / +336 161 602 74

e...@clascertification.com

Clas certification - 2018 - Tous droits réservés - Mentions légales - Design : Pygmalis - Intégration : Ingeitec